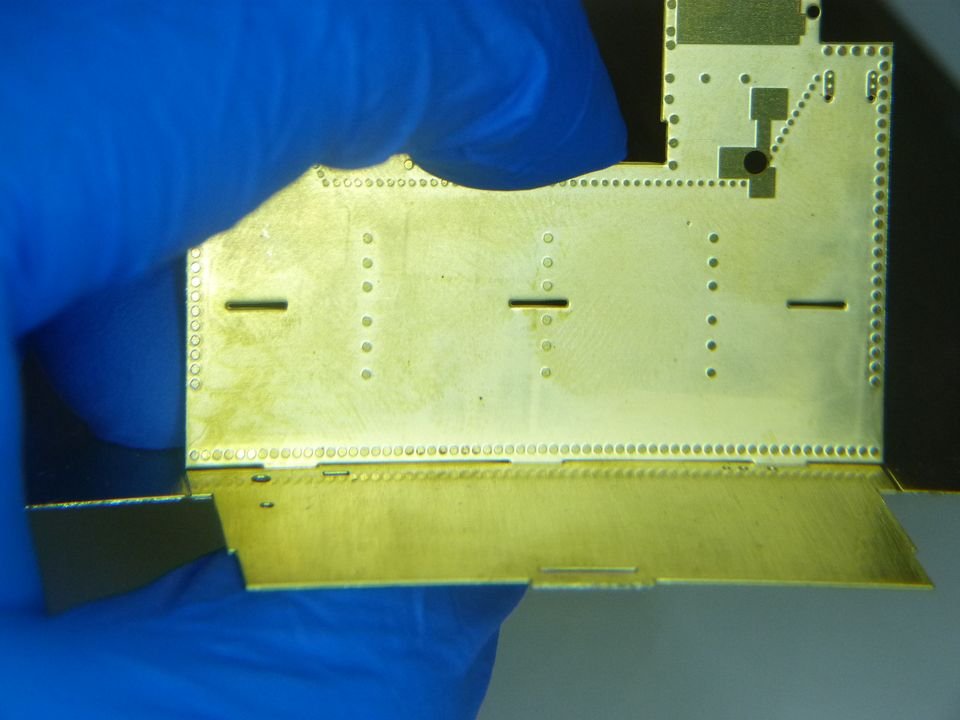

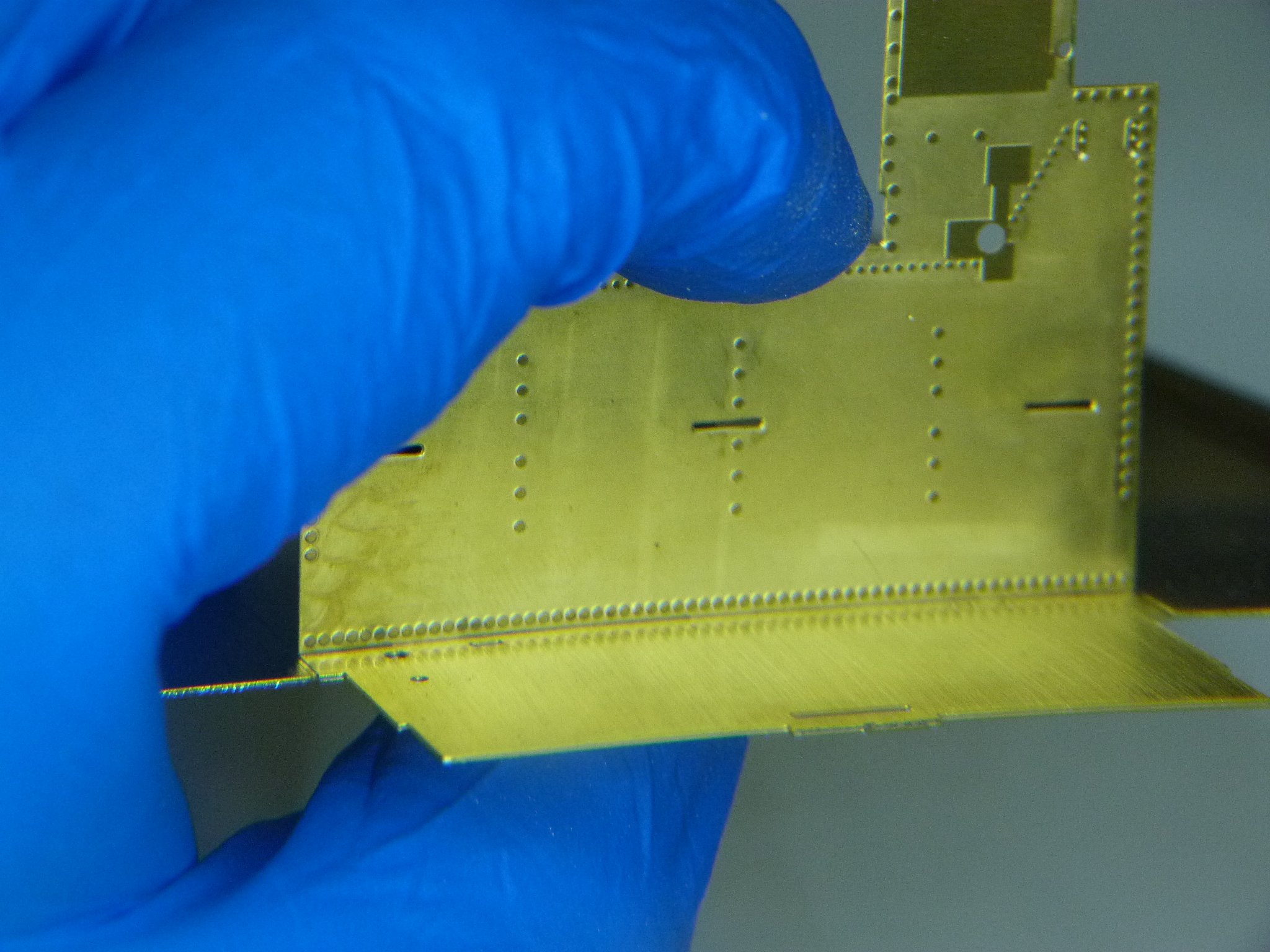

The etch cusp

Under magnification there is a cusp the runs along the edge of an etched brass part.

It can be a point or a D shape and this can interfere with parts fitting.

See the two photos below. I haven’t cleaned off the cusp and as you can see, the tender front wall doesn’t quite sit down. A quick run around with the file and there she goes, a drop in fit with no interference, next step is to solder into place. The interference is quite visible on this kit in the 3 horizontal holes in the middle of the tender wall…

The cusp doesn’t seem to be a constant, the size of the interference can vary from nothing to substantial, down to the processes and design of the manufacturer.

Before cussing a kit doesn’t go together, check the interference or cusp.